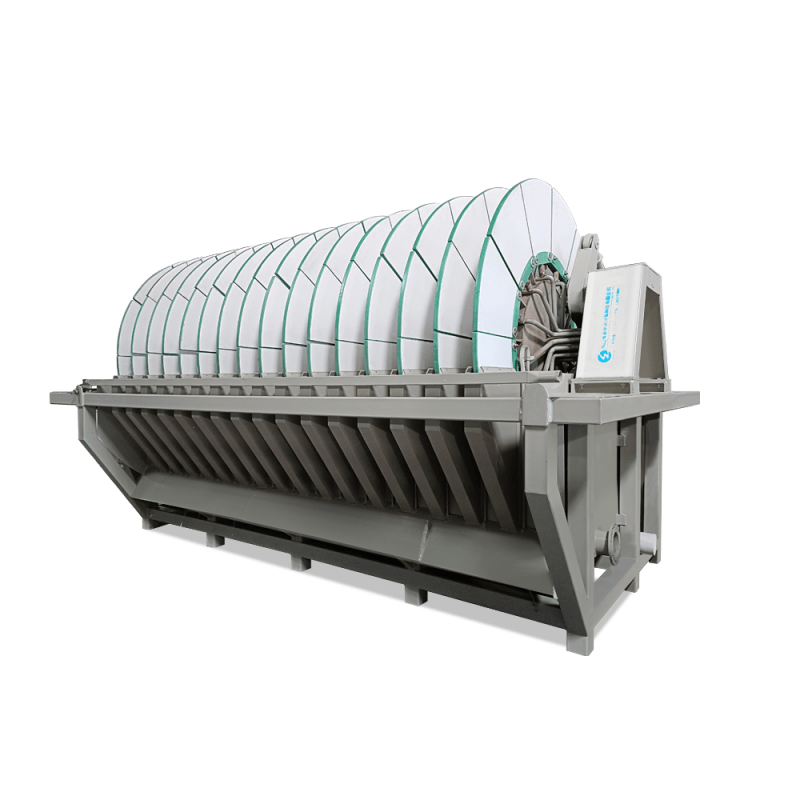

Vacuum Ceramic Filter Press-Small Diameter

Ceramic filter is an adcanced solid-liquid separation equipment in the world. Its core componect, ceramic filter plate, was successfully developed by Otto Kunpu Company of Finland.

The aperture of ceramic filter plate is usually 1-5 micrions (the most commonly used is 1.5-2.0 microns). Such microppres can produce strong capilary action.

When disc filter works,only liquid becomes filtrate through micropores under the action of vacuum pump, while solid and gas are blocked on the surface of filter plate to become filter cake, thus realizing solid-liquid separation.

The ceramic filter can be widely used for dewatering sand and gravel aggregates, coal, stone, ceramics, non-ferrous metal mines and other industries, and has a wide range of applications.

The processing capacity is large, and the energy saving effect is obvious. Adopt PLC program automatic control, automatic feeding, automatic cleaning, reduce the labor cost of system operation. It has an automatic fault alarm system, fault screen display function, high and low liquid level alarm display, and automatic elimination or shutdown for manual processing. Reasonable structure, reliable operation, the main transmission parts are made of stainless steel, to ensure that its service life can reach more than 10 years. The moisture content of the material after filtration and dehydration is very low, which can greatly reduce the transportation cost and loss. Since the filtrate is clear, it can be reused and reduced emissions, which is in line with the current environmental protection trend of cleaner production.PRODUCT INTRODUCTION

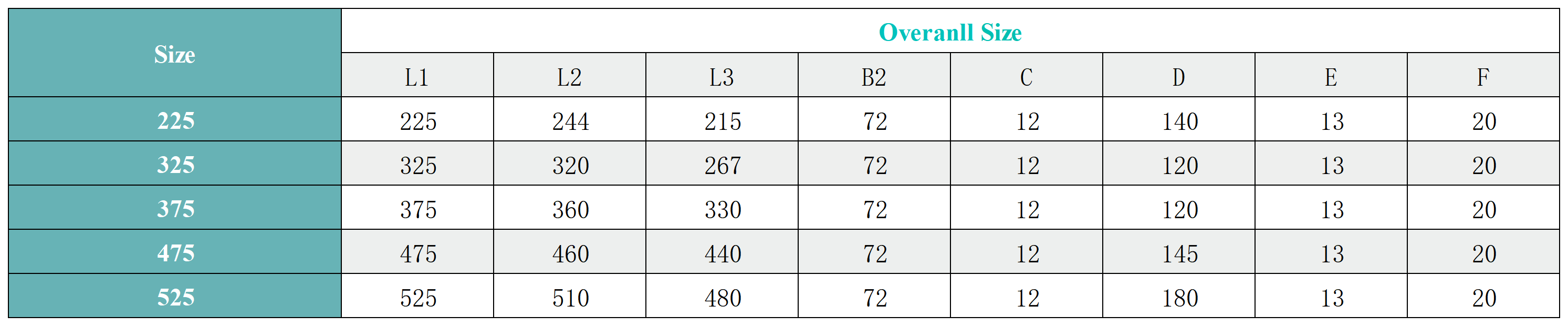

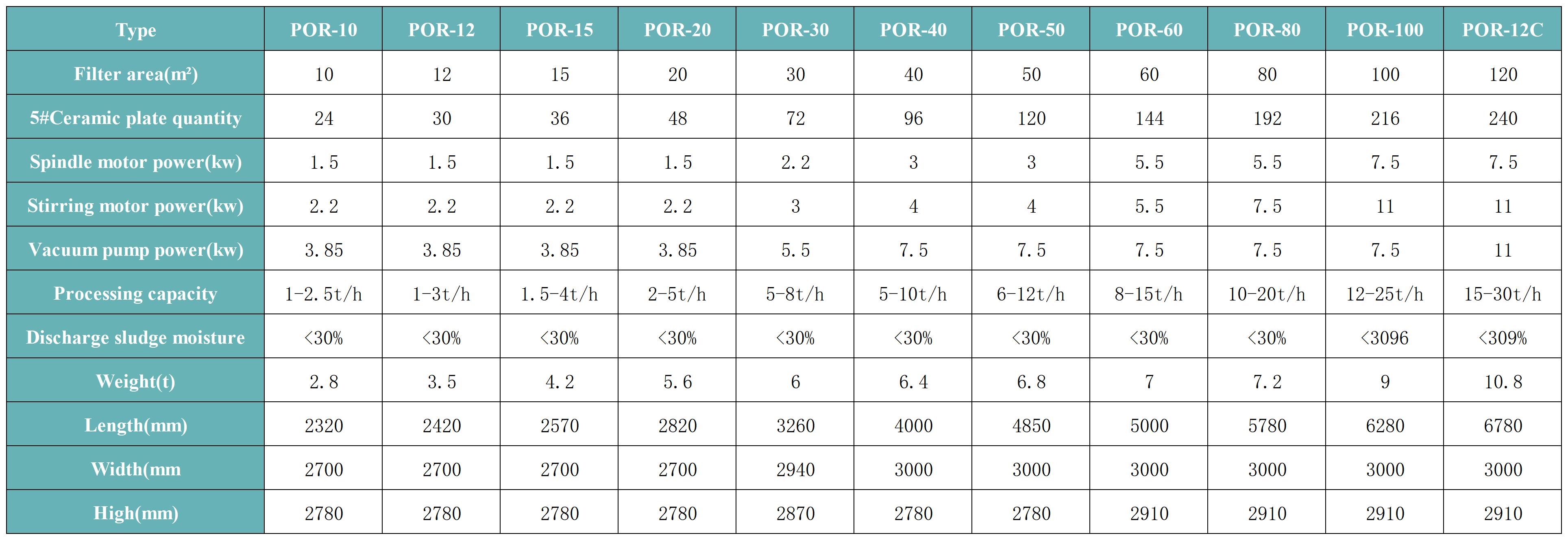

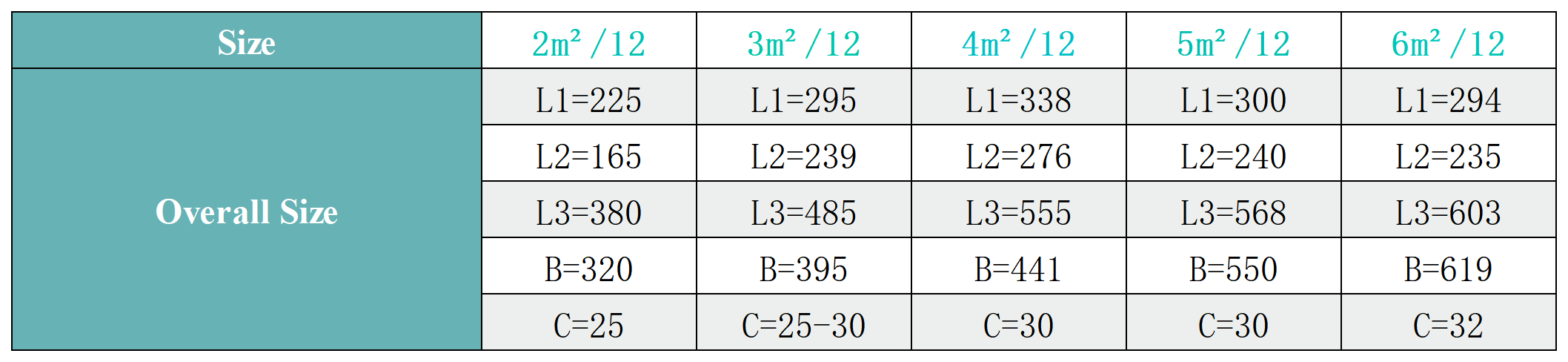

TECHNICAL PARAMETERS

ACCESSORY PARAMETERS

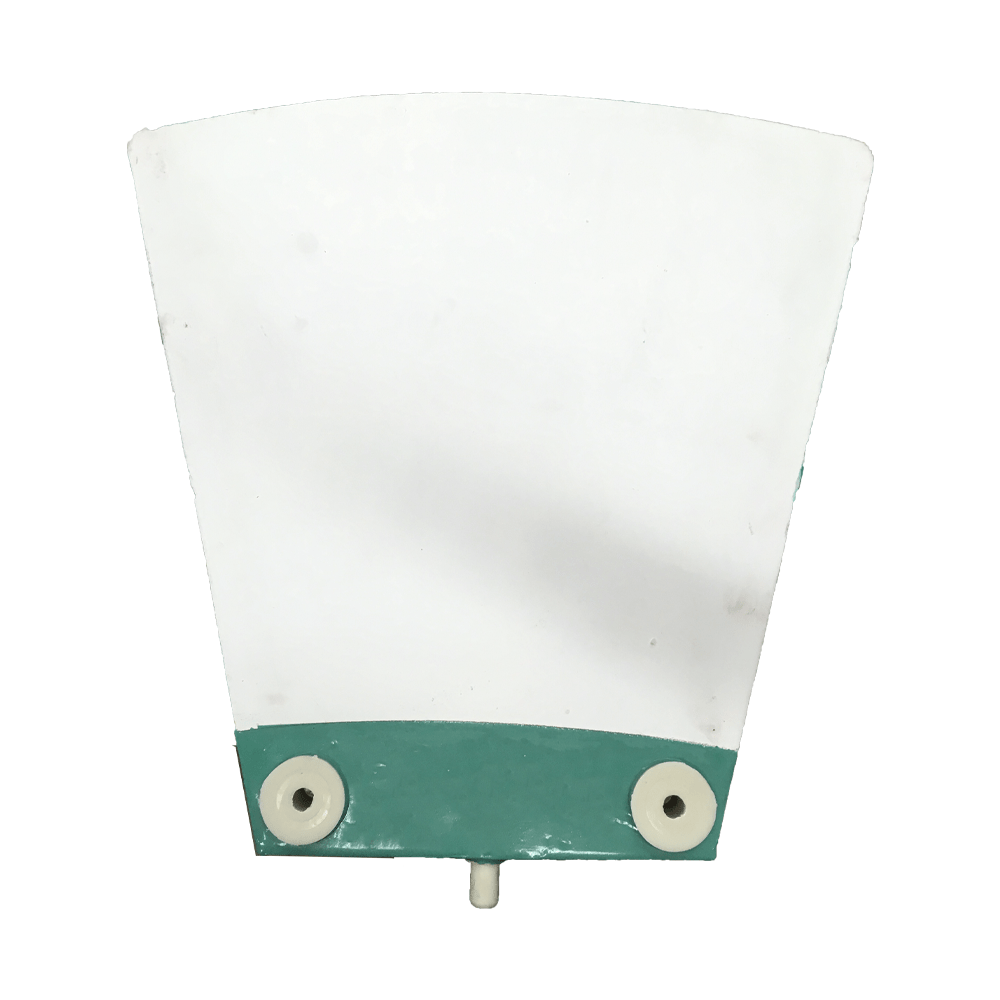

CERAMIC FILTER PLATE

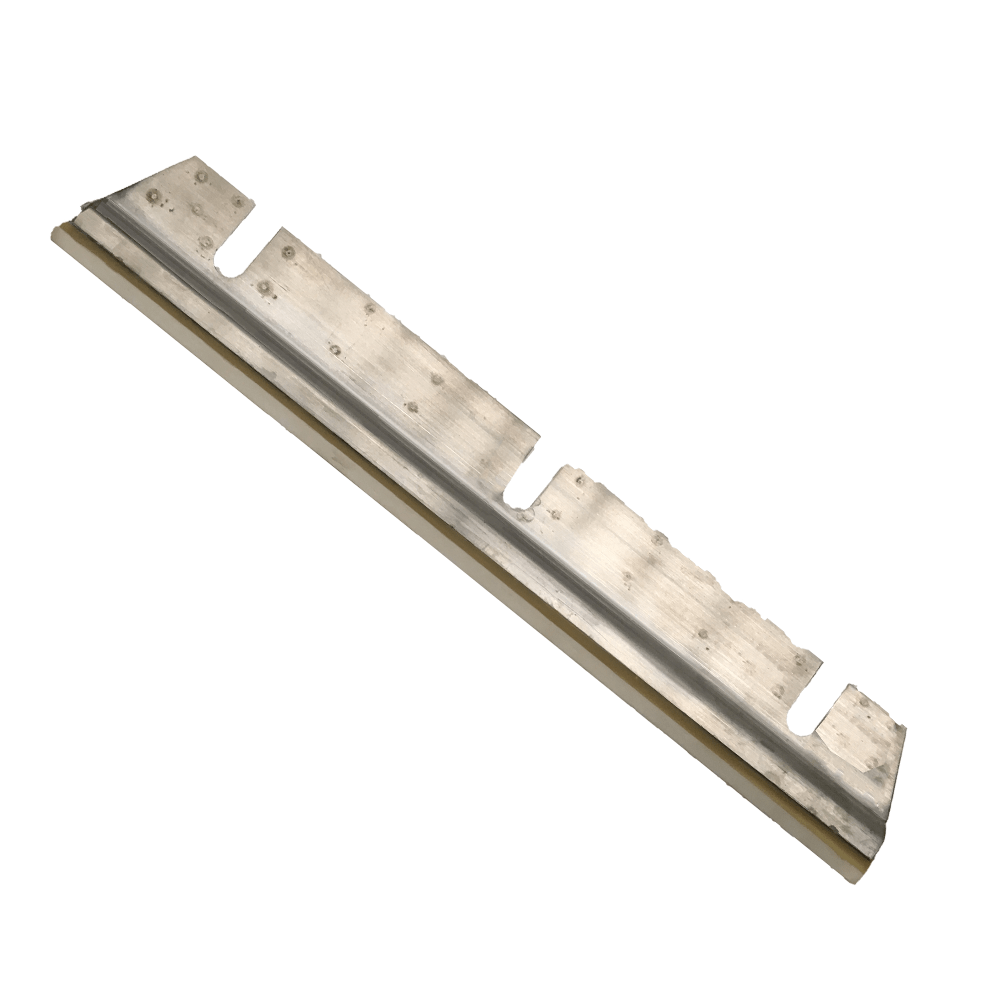

CERAMIC SCRAPER

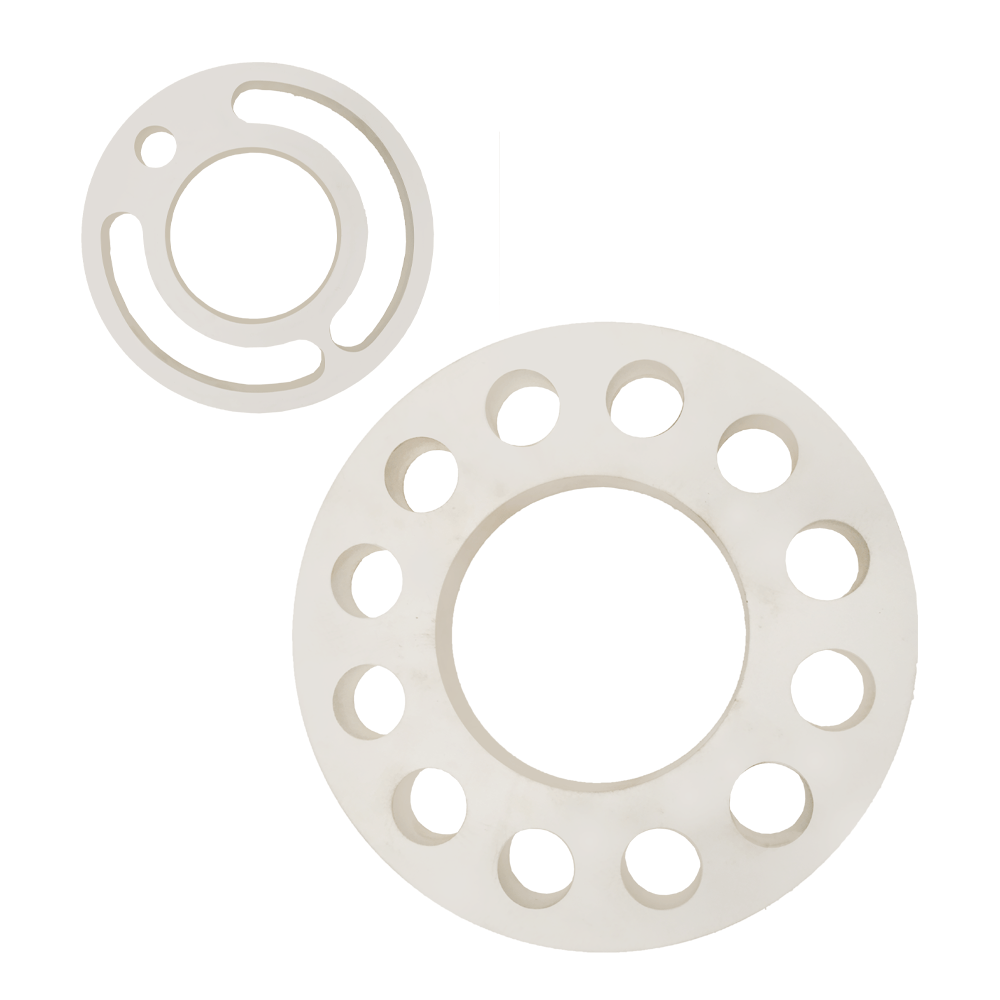

CERAMIC FRICTION RING

CERAMIC FILTER PLATE

CERAMIC SCRAPER