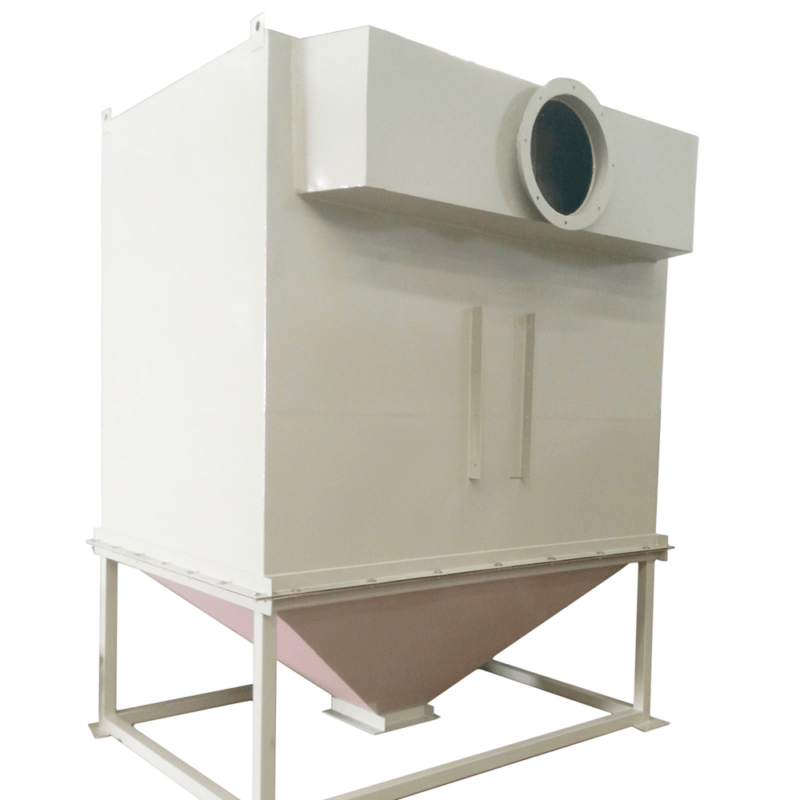

Double Bucket Bag Dust Collector

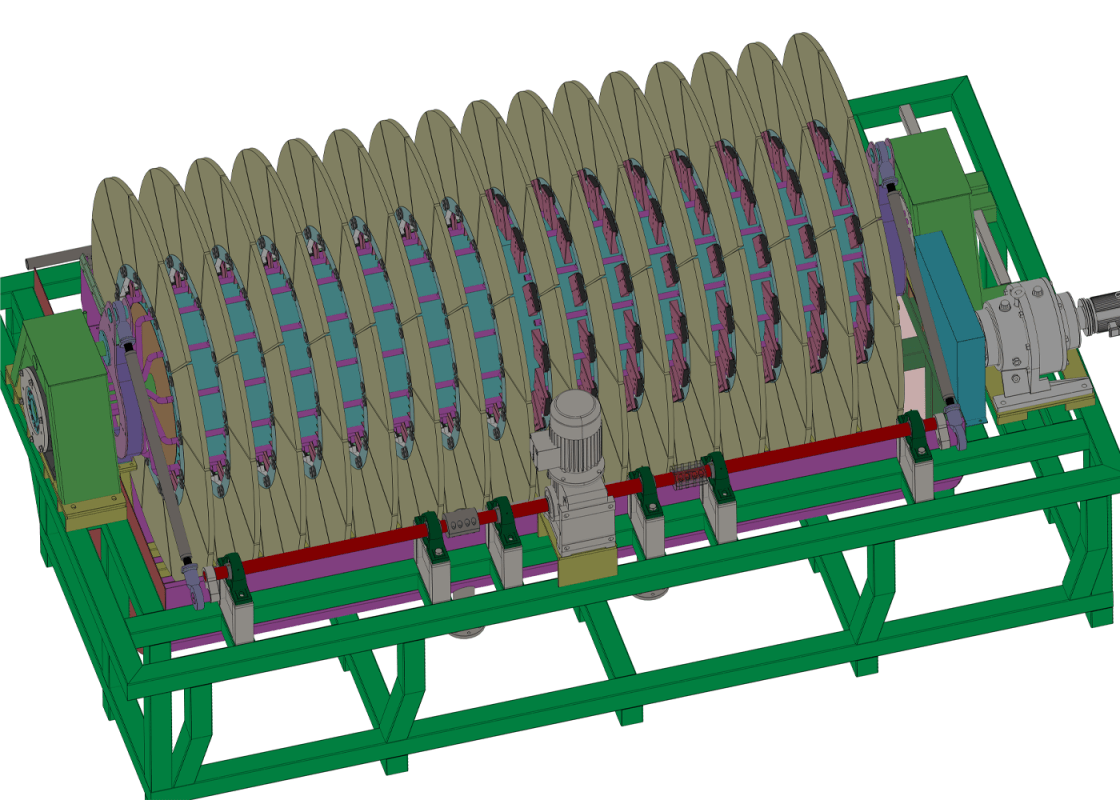

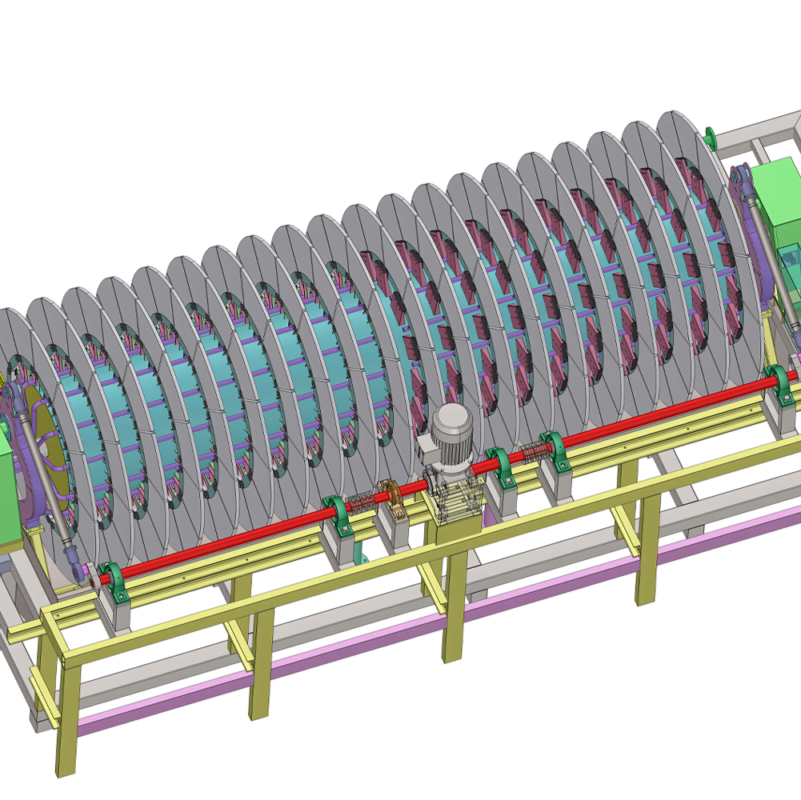

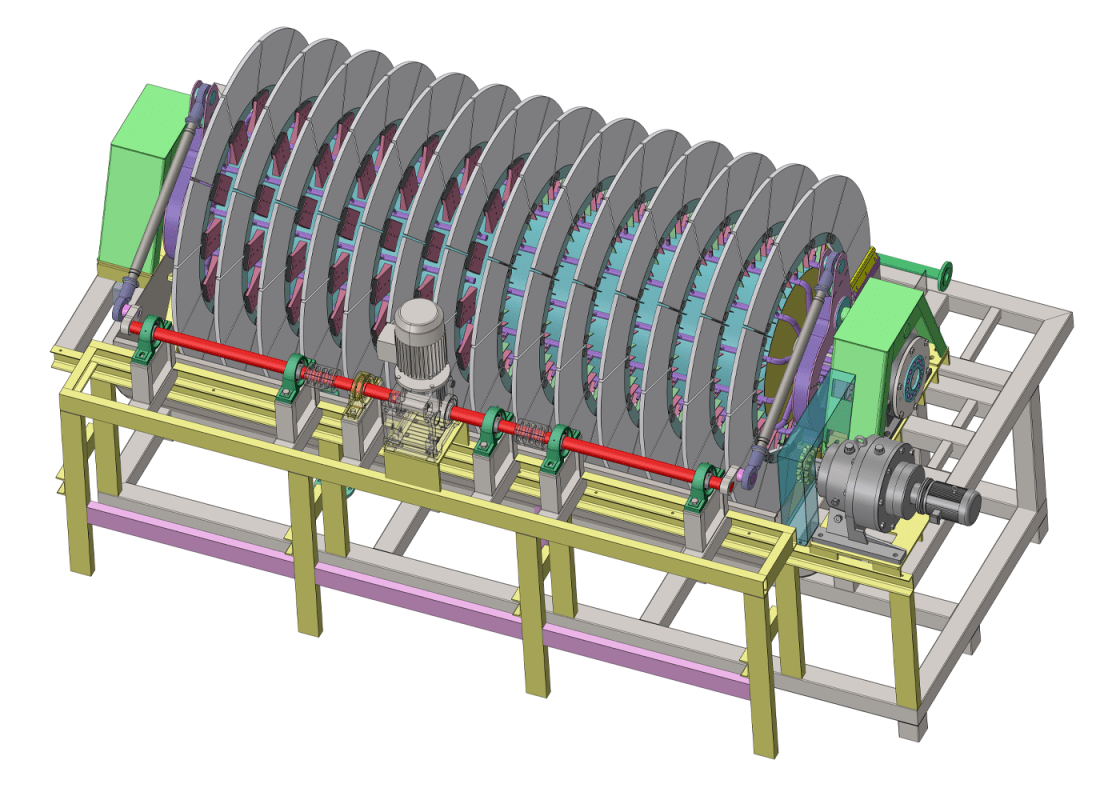

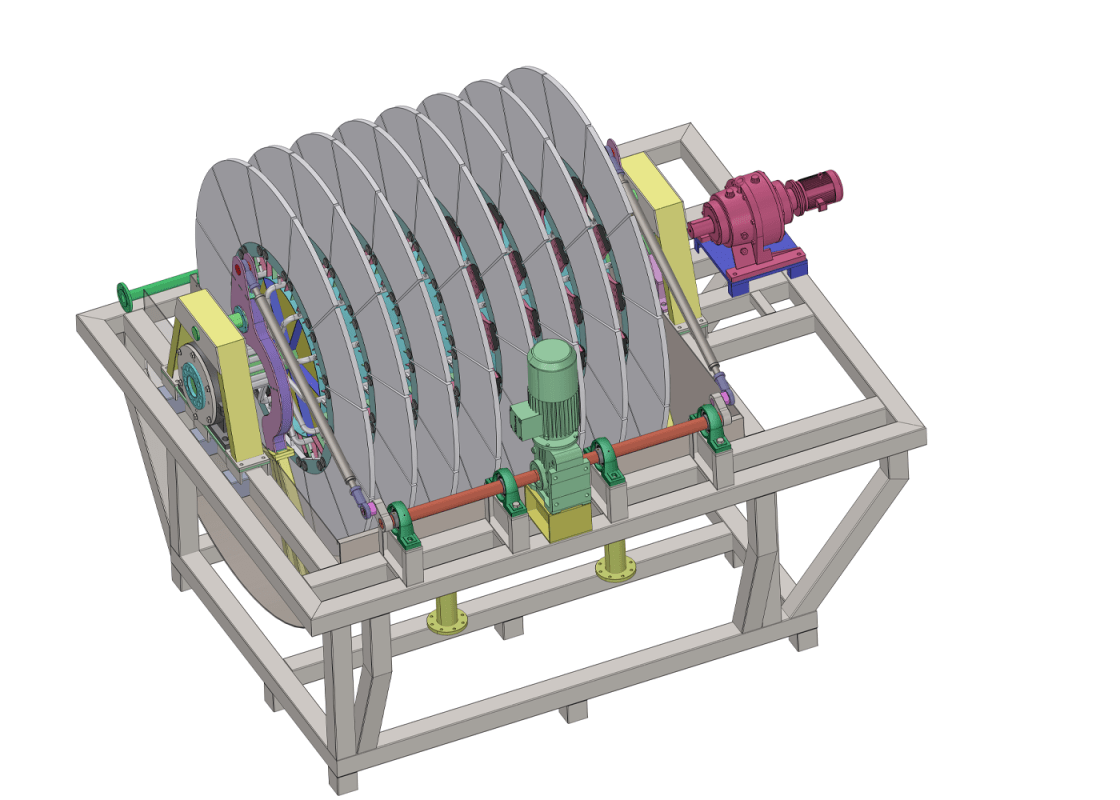

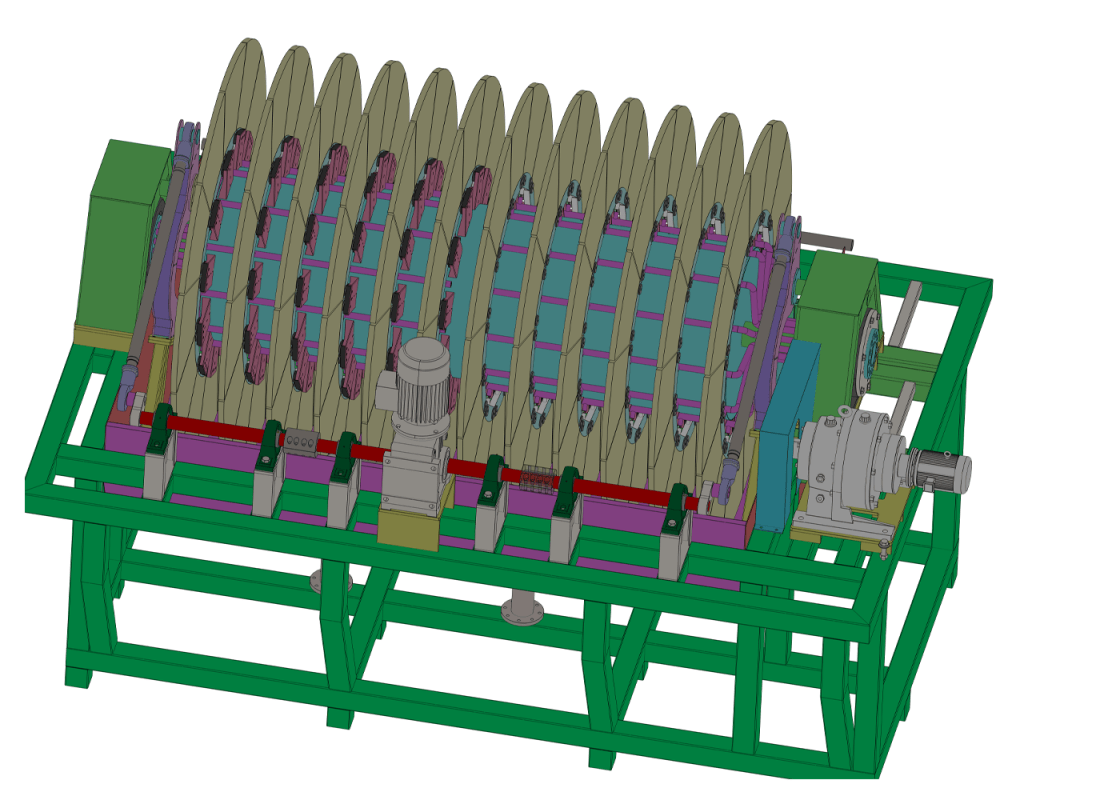

Design principle is the combination of the company based on many of the polished form factor device, stirring dust station supporting dedusting unit designed and manufactured, which increase in fan support and installation structure had many vacuums, located at the end of the pulley features such as flexibility, convenient cleaning.

Woodworking, grinding, sandblasting, grinding wheels, cutting, cleaning powder, cotton dust, cement dust, saw dust, metals, coal, iron, and other design, it has the advantage of cheap, high recovery rate, easy to clean, easy to use.

PRODUCT INTRODUCTION

- Low resistance, high flow, high efficiency.

- According to the system processes of the low resistance, high flow and high efficiency optimize network design, reduce system resistance loss;

- Using flow control method, allows the system piping economic flow rate of 16-19m / s;

- Good adaptability to load change, particularly adapted to capture subtle and dry dust, the dry dust collected to facilitate processing and recycling.

- A simple routine maintenance and the replacement of the cloth bag can be completed in the state of non-stop.

SYSTEM CHARACTERISTICS

Dust air come into dust collector through air input, and big dust grain will drop into hopper, small and micron dust will be stopped outside filter bag surface, and clean air go through filter bag and be suctioned into atmosphere.

As filtration works continuously, dust outside filter bag surface increase continuously, then resistance of dust collecting increase, then certain room’s transferring valve will be closed and its filtration stop. Compressed air will go into filtration room in converse direction, and blow dust outside filter bag surface, then transferring valve will open, and filtration work again. Dust removing turns to next filtration room. Whole dust removing process take place alternately in all filtration rooms one by one.

SCOPE OF APPLICATION

It is widely used in dust collection systems such as crushing packaging storage root clinker cooler and various grinding machines in cement plants, as well as in dust collection of waste gases such as metallurgical, chemical mechanical and civil boilers.

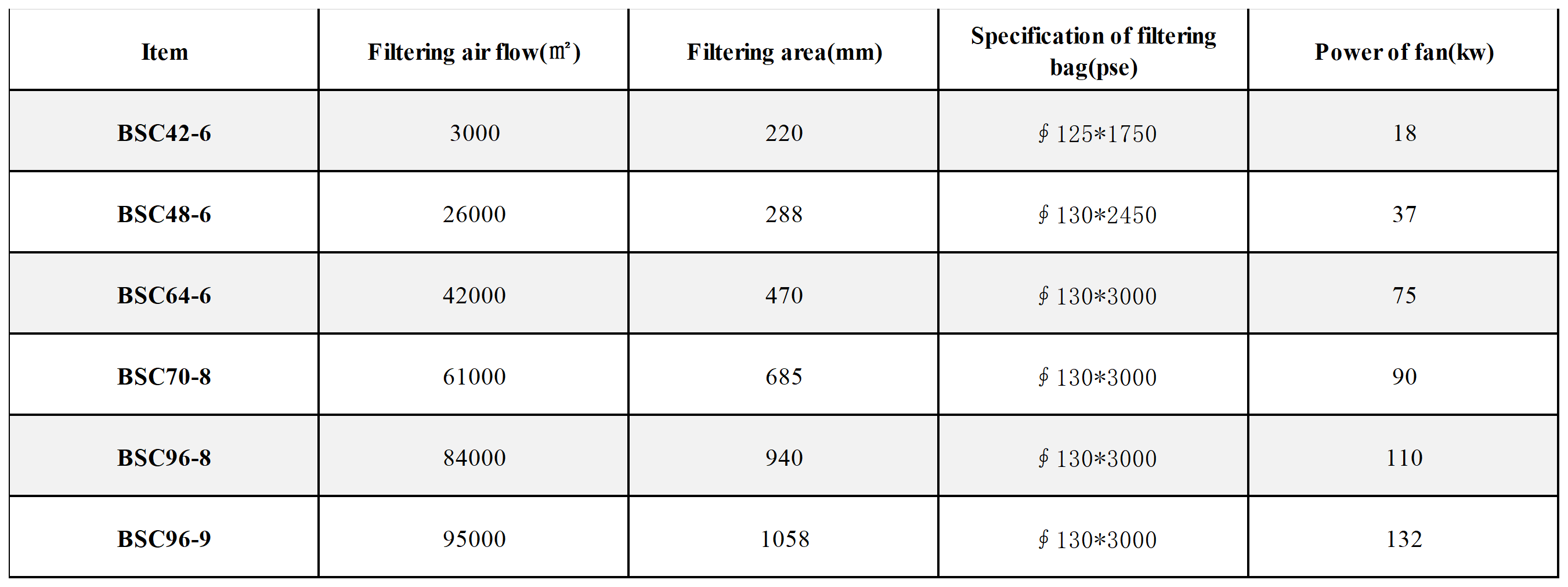

TECHNICAL PARAMETERS