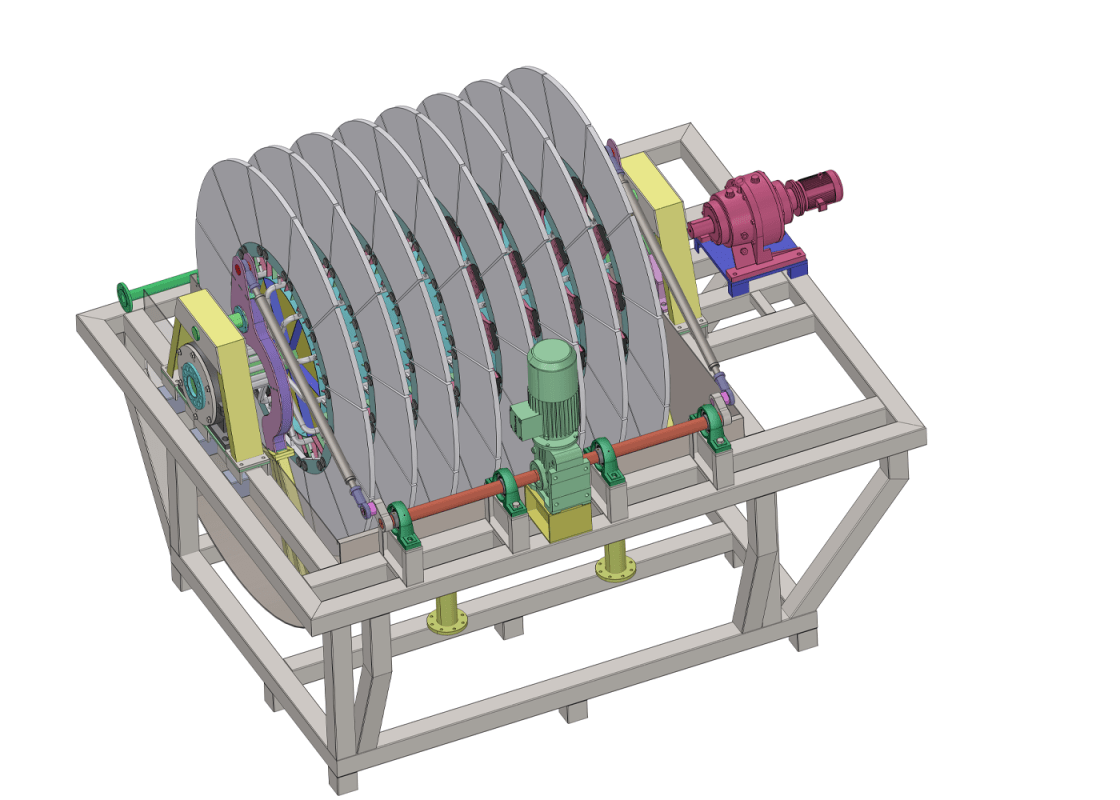

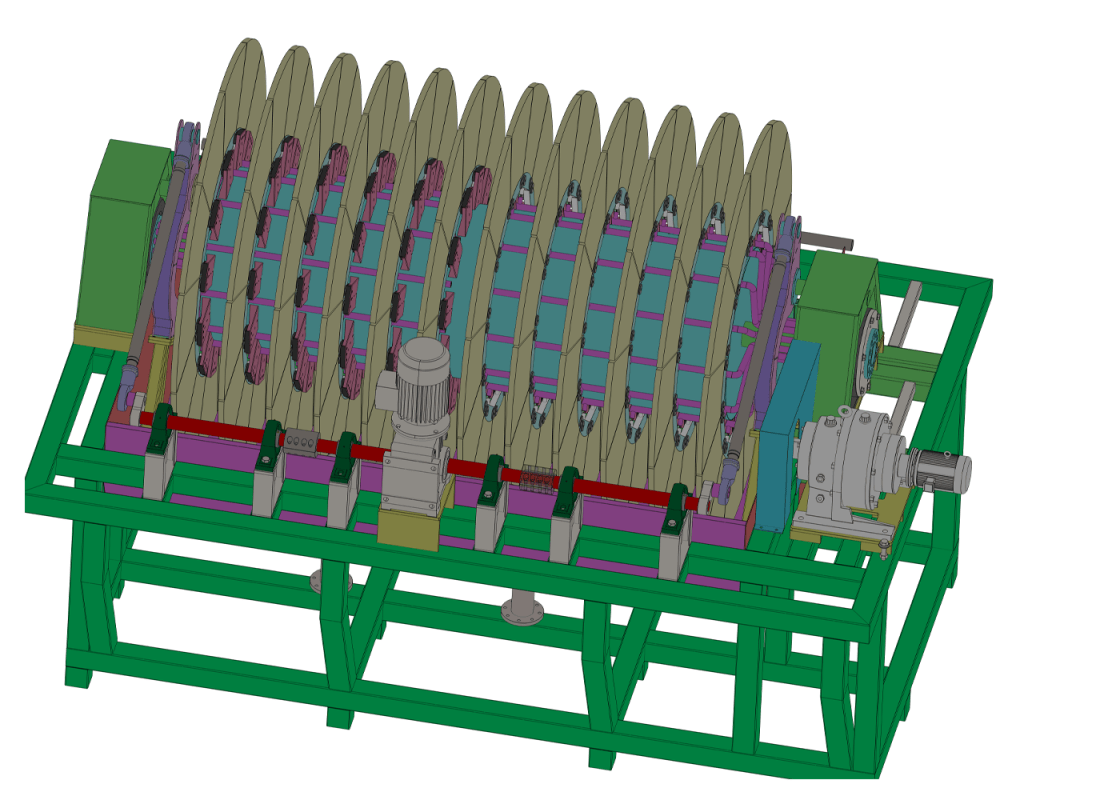

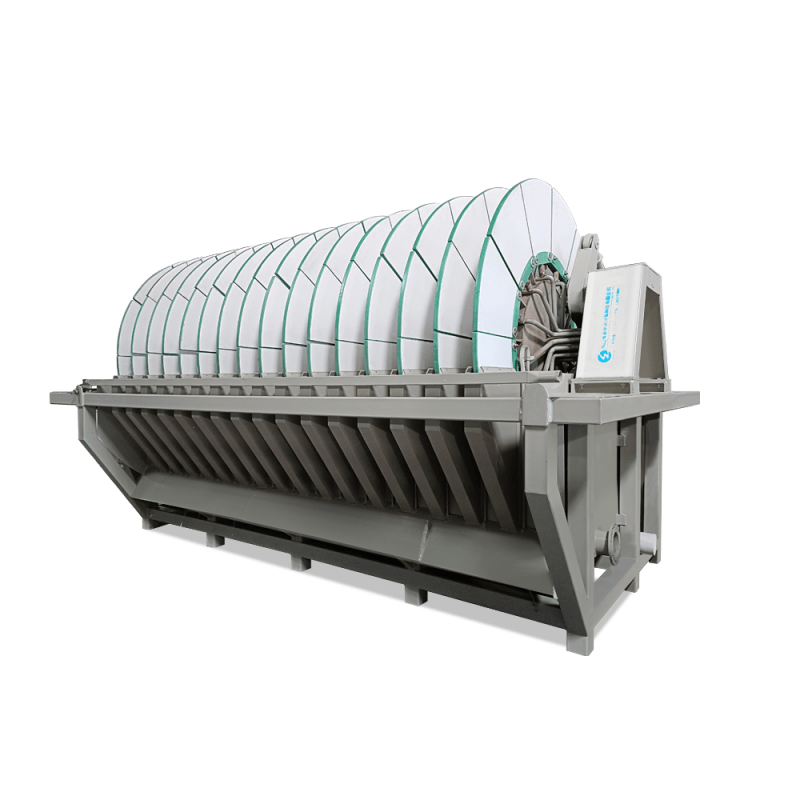

Plate And Frame Filter Press

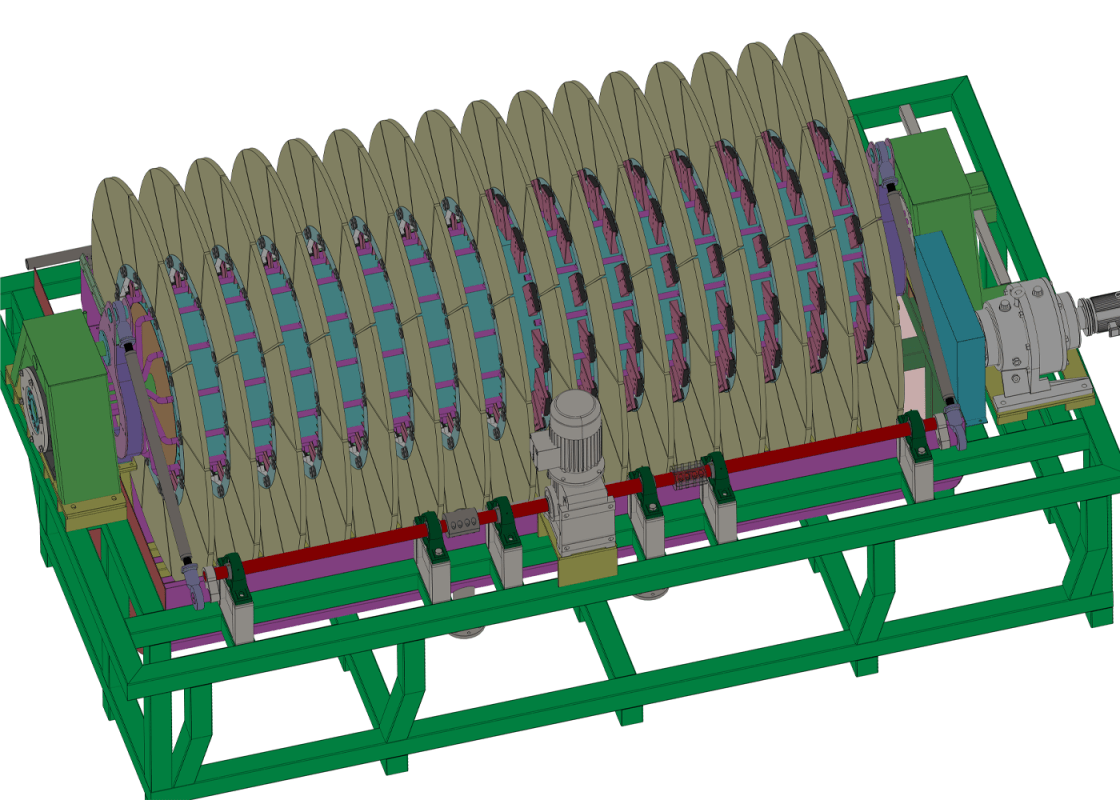

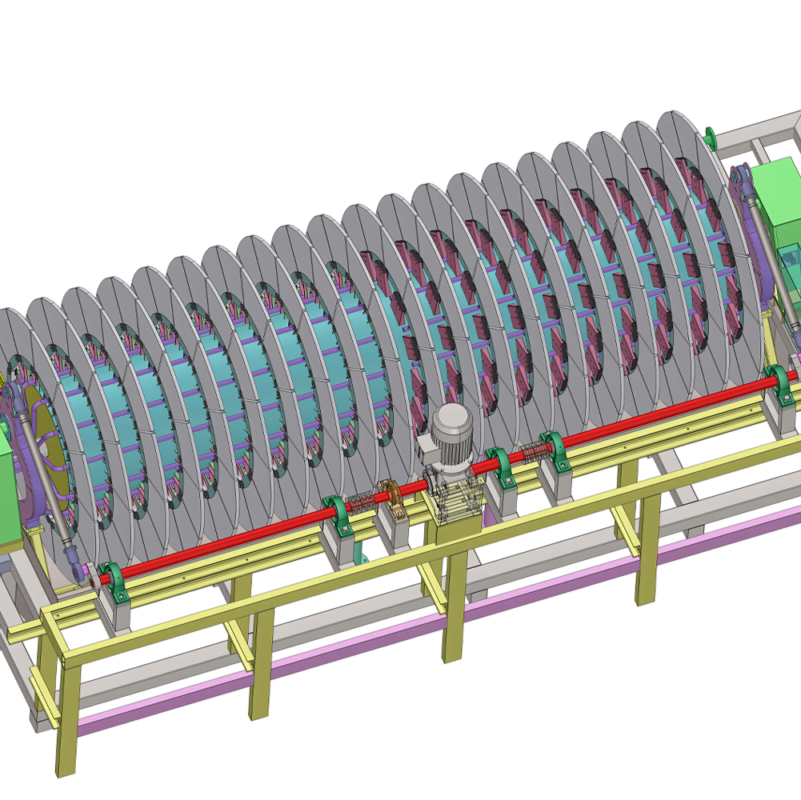

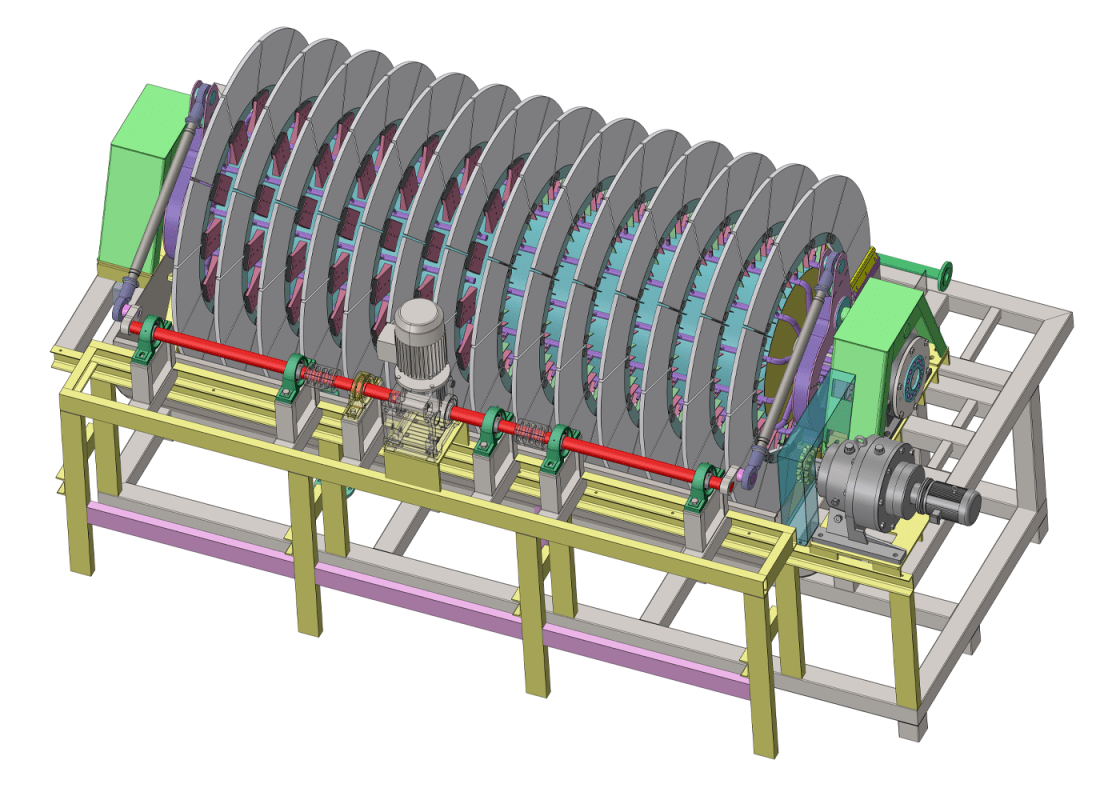

The hydraulic cylinder is used as the driving device for pressing and loosening the filter plate; the automatic pressure maintaining device makes the operation easier and ensures the safety of the operator.

It has the characteristics of high strength, light weight, corrosion resistance and impact resistance; the frame is made of full-width welding of international plates, with a reasonable structure, strong and durable.

The main beam is fully covered with 304 stainless steel, and the surface of the whole machine is anti-corrosion treatment to prolong the service life.

Using PLC program control (optional) electromechanical-hydraulic integrated program-controlled structure, saving space and beautiful appearance.

PRODUCT INTRODUCTION

The plate and the frame are arranged alternately and covered with filter cloth on both sides of the filter plate. The plate and the frame are compacted by a compaction device, that is to say, a filter chamber is formed between the plate and the frame. There are small holes in the same part between the upper end of the plate and the frame, which become a channel after compaction. The sludge is pressurized to 0.2~0.4 MPa.The channel enters the filter chamber.The surface of the filter plate is engraved with grooves, and the lower end is drilled with channels for the discharge of filtrate.Under the pressure, the filtrate is discharge through the filter cloth, along the grooves and channels to dehydrate the sludge.

SCOPE OF APPLICATION

Ceramics,stone, glass, metallurgical minerals, coal washing, sand washing, paper making, food processing, chemical pharmaceuticals, electroplating, textile printing and dyeing,leather,municipal sewage and other industries.

SYSTEM CHARACTERISTICS

It has wide application scope, low moisture content of cake, clear filtrate, low energy consumption, stable and automatic operation, and meets the design of high-demand operation conditions, long service life.

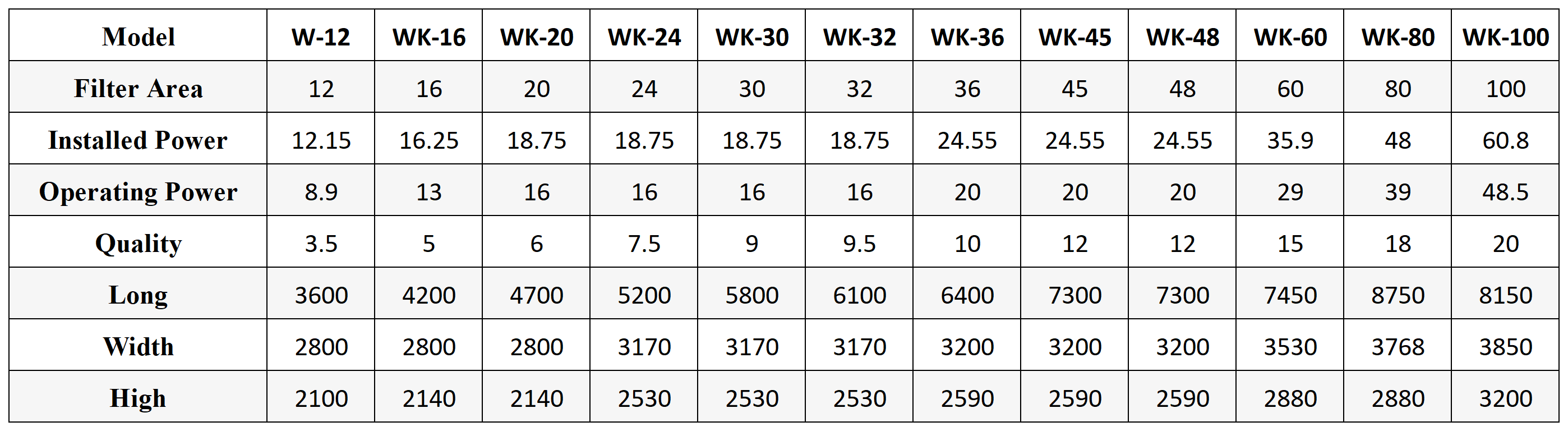

TECHNICAL PARAMETERS