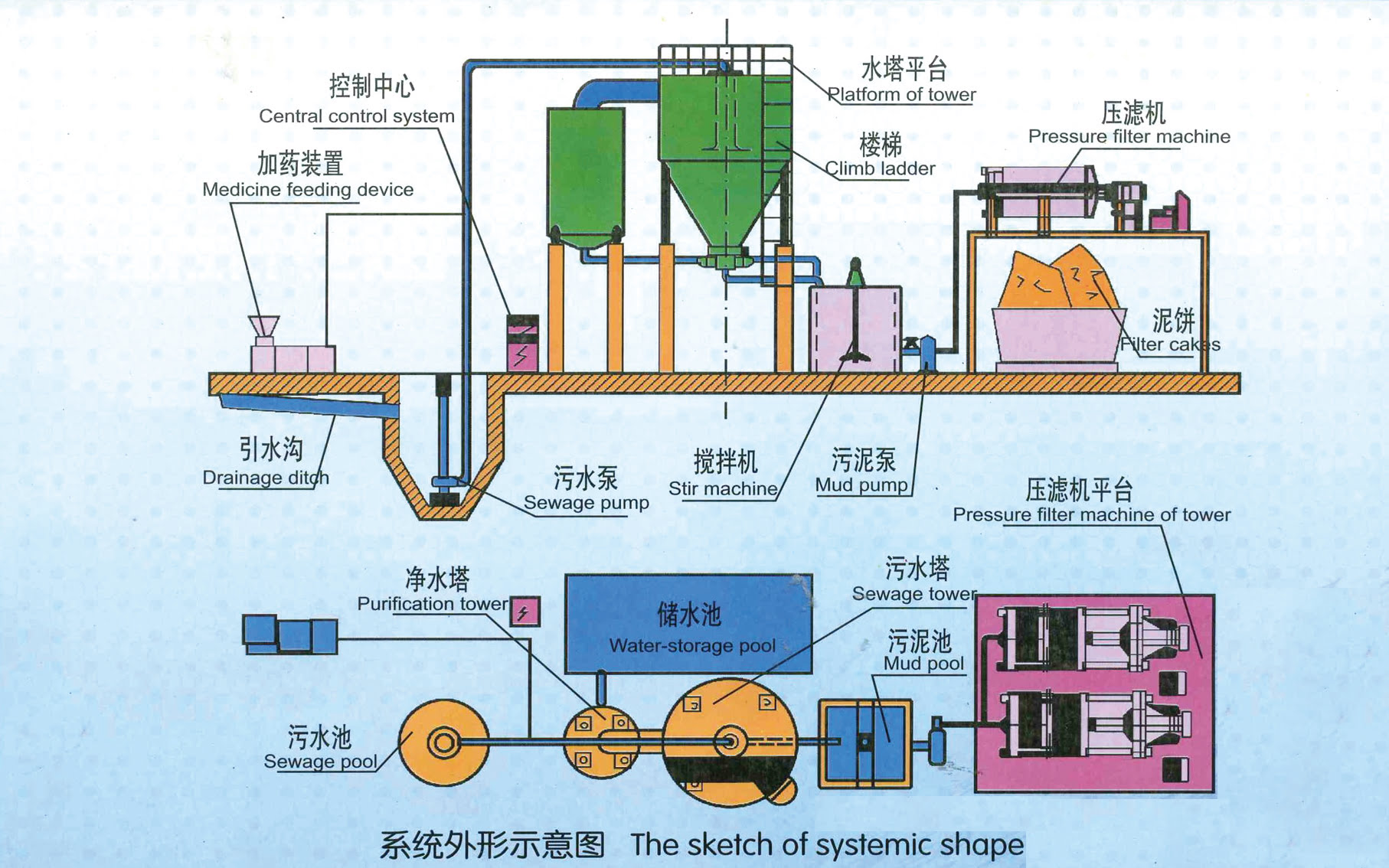

System Introduction

The tower sewage treatment system is a high-tech, environmentally friendly and energy-saving product designed and manufactured specifically for sewage purification and recycling for the ceramic industry. This system is exclusively designed using independent innovative technology and abandoning the shortcomings of traditional pool sedimentation treatment methods. The system uses a vertical sedimentation tower, so it is also called a tower sedimentation and slag removal system.

This system has been increasingly accepted by stone and ceramic enterprises due to its flexible combination methods, small footprint, high degree of circulating water purification, and large processing capacity.

The whole system adopts automated intelligent control, with few maintenance personnel and low labor intensity. Closed pipe connections are used to ensure a clean and tidy site environment and are suitable for related enterprises of all sizes. The system integrates precipitation, concentration, press filtering and slag removal. It has complete functions, advanced technology and good processing effect. It is the first choice product for stone factories and ceramic factories.

Sewage Conveying System

The large particle sedimentation system consists of one or more stages of sedimentation tanks and a sand removal machine. After entering the startup interface, parameter settings and manual operations can be performed. The specific parameters are set according to the on-site sewage volume and the actual need to process large particles. . Entering the manual operation interface can independently control the start and stop of the slurry pump and vibrating screen machine. The vibrating screen machine is linked to the slurry pump and synchronized with the start and stop of the slurry pump.

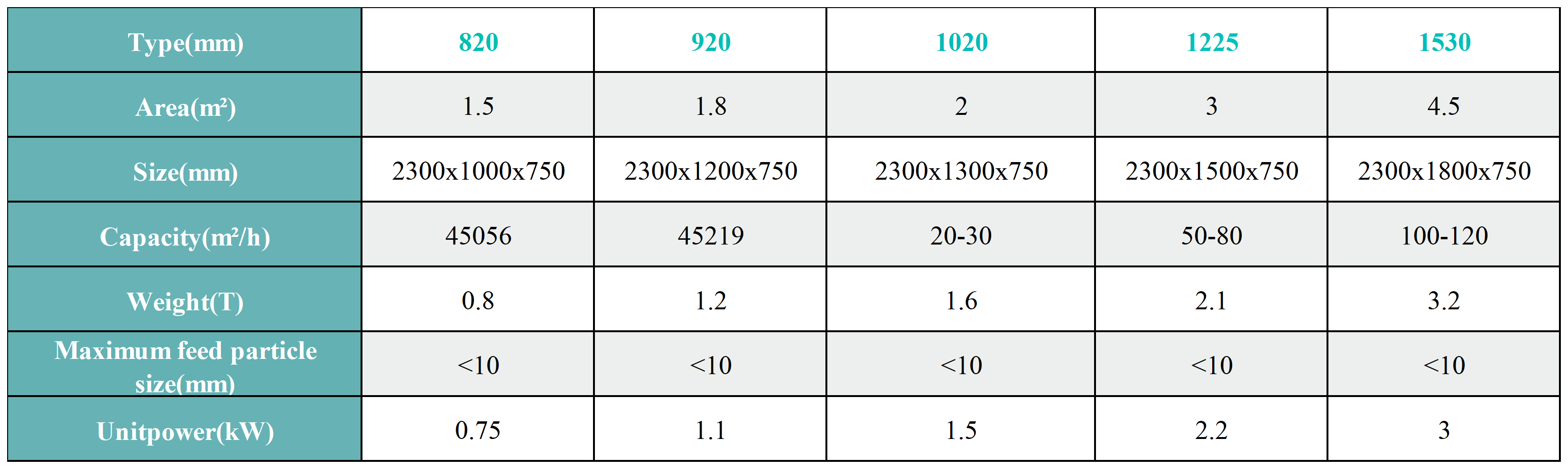

Technical Parameters OF Square Vibrating Screen Machine

Technical Parameters OF Circular Vibrating Screen Machine

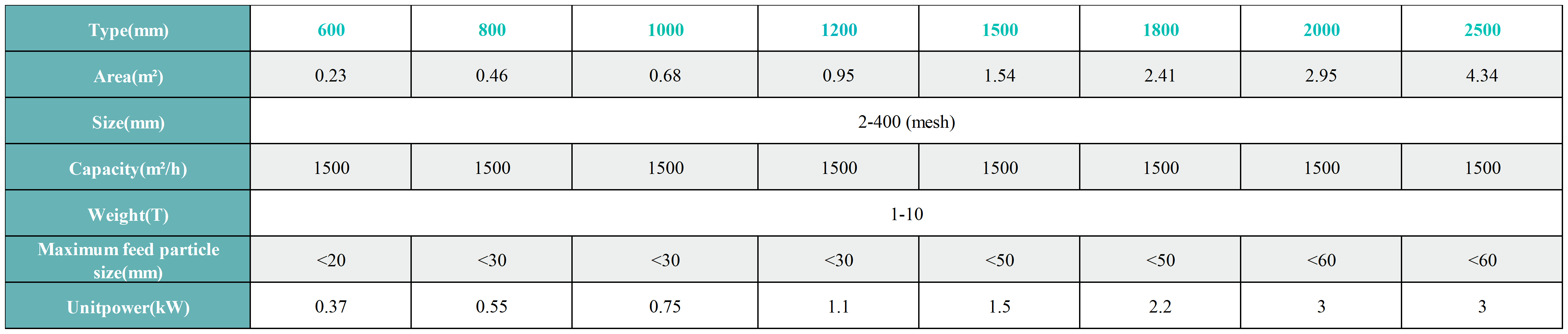

Technical Parameters OF Spiral Sand Pumping Machine

Tube Pump Set

Circular Vibrating Screen Machine

Spiral Sand Pumping Machine

Technical Parameters

Auto Dosing Machine Series

The three-chamber automatic dosing device is an automatic and continuous flocculant dissolving device, and the concentration of the prepared solution is 0.1%-0.3%. Both the preparation tank and the aging tank are equipped with agitators to fully ensure the dilution and aging of the flocculant. In addition, when the storage tank solution is insufficient, the lower liquid level alarm system will be triggered, and all systems will stop and alarm. This device is characterized by high degree of automation, stable performance, reliable operation and simple operation.

The PAM dosing device consists of a dissolving tank, several pipes, valves, etc. The metering pumps are configured for use and backup, which makes it convenient for users to perform maintenance and replace accessories without stopping the machine.

The main components of this device are: drug storage tank, dissolution tank, mixer, metering pump, pipeline filter, return pipe and drug suction pipe, drug discharge pipe, dissolution tank overflow pipe, vent pipe and necessary pipes Valves and fittings, pipe fittings and valves required for safety.

PAC automatic flocculant dispensing and dosing device is an intelligent, fully automatic, continuous and integrated flocculant dispensing and dosing device.

This device consists of a water supply system, a dry powder dosing system, a dissolving and aging system, a control system, and a liquid dosing system.

The flocculant automatic dissolving and dosing device consists of the following parts: 1. Water supply system 2. Dry powder dosing system 3. Dry powder premixing system 4. Integrated three-tank combination box